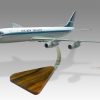

Airbus A300B Original House Livery Model

Production Time 8 to 10 weeks

Shipment is by FedEx, UPS or DHL International Express Courier with a normal door-to-door delivery time worldwide of within 2-3 business days after dispatch. Due to the current volatility of world fuel prices, the amount mentioned here is our best estimate for DHL and UPS and may be subject to change at the time of shipping.

Product statistics

Length: 17 in (43.2 cm)Wingspan: 14 in (35.6 cm)

Height: 5.2 in (13.2 cm)

Scale: 1:125

USD $219.50

Manufacturer: Airbus Industries

Production Time 8 to 10 weeks

-

United States dollar ($)

-

Pound sterling (£)

-

Euro (€)

-

Australian dollar ($)

-

Canadian dollar ($)

-

Singapore dollar ($)

-

Swiss franc (CHF)

-

Japanese yen (¥)

-

Danish krone (kr.)

-

Hong Kong dollar ($)

-

Norwegian krone (kr)

-

Swedish krona (kr)

General Product Description

Our ModelBuffs Airbus A300B Original House Livery Model exhibits unique, unrivaled quality and detailed design to come as close as possible to the accuracy of the actual plane. It comes as standard with a robust, durable base or stand which is available in a variety of different finishes designed to match your own personal requirements including solid wood, wood with polished metal supports or adjustable wood wall mount and will be ready within about 8-10 weeks from placement of order.

The Airbus A300B Original House Livery Model is made of the finest kiln dried renewable mahogany wood (commonly known as Lauan or Meranti) which has undergone many stages of carving and meticulous and careful sanding giving the beautiful finished museum quality masterpiece. Many collectors and model connoisseurs demonstrate their preference for genuine handmade and hand painted mahogany wood models rather than plastic or die cast (diecast) alternatives due to the overall look and totally different feel of the item - we trust you will find the same. We can, however, if required produce the same model in Solid Cast Resin so just click and contact us us for further information. Our craftsmen and gifted artisans ensure that our finely handcrafted model airplanes match the precise blueprint details of the original aircraft. The paint scheme, markings and parts are closely matched, reflecting the original aircraft. This stylish top-quality desktop replica model will surely enthrall anyone who receives this as a gift and for sure one of the most appropriate and desirably collectable gifts for any aviation enthusiast and avid aircraft collector whilst also displaying a perfect resemblance to the actual aircraft.

If you require we can also make the Airbus A300B Original House Livery Model in any other airline, private livery or colour scheme you require and if necessary in a different size or scale. Just click here to contact us with a description or photographs of what you require, and we will let you have a quotation for the necessary customization by return email. We can also make bespoke scale replicas of any other private / civil commercial airliner or airliners, helicopter, glider, gliders with engines, military jet, warplane jets, propeller warplanes, biplane, triplane, tail fin, spacecraft, rocket or NASA model you require in any airline, military or civilian livery or colors. We also produce model airships, blimp, dirigible, blimps, boat and ship collectibles. Wall plaque or seal for military, government or private customers. Again, by clicking here to contact us just let us know exactly what you need.

The mission requirements were given in 1966 by Frank Kolk, an American Airlines executive, for a Boeing 727 replacement on busy short- to medium-range routes such as US transcontinental flights. His brief included a passenger capacity of 250 to 300 seated in a twin-aisle configuration and fitted with two engines, with the capability of carrying full passengers without penalty from high-altitude airports like Denver. American manufacturers responded with widebody trijets, the McDonnell Douglas DC-10 and the Lockheed L-1011 Tristar, as twinjets were banned from many routes by the FAA.

American Airlines A300In September 1967, the British, French, and German governments signed a Memorandum of Understanding (MoU) to start development of the 300-seat Airbus A300. An earlier announcement had been made in July 1967, but at that time the announcement had been clouded by the British Governments support for the Airbus, which coincided with its refusal to back British Aircraft Corporations (BAC) proposed competitor, a development of the BAC 1-11 – despite a preference for the latter expressed by British European Airways (BEA).

In the months following this agreement, both the French and British governments expressed doubts about the aircraft. Another problem was the requirement for a new engine to be developed by Rolls-Royce, the RB207. In December 1968, the French and British partner companies (Sud Aviation and Hawker Siddeley) proposed a revised configuration, the 250-seat Airbus A250. Renamed the A300B, the aircraft would not require new engines, reducing development costs. To attract potential US customers, American General Electric CF6-50 engines powered the A300 instead of the British RB207. The British government was upset and withdrew from the venture; however, the British firm Hawker-Siddeley stayed on as a contractor, developing the wings for the A300, which were pivotal in later versions impressive performance from short domestic to long intercontinental flights.[citation needed] (Years later, through British Aerospace, the UK re-entered the consortium.)

Airbus A300B4-600Airbus Industrie was formally set up in 1970 following an agreement between A eacute;rospatiale (France), the antecedents to Deutsche Aerospace (Germany) . They were to be joined by the Spanish CASA in 1971. Each company would deliver its sections as fully equipped, ready-to-fly items.

In 1972 the A300 made its maiden flight. The first production model, the A300B2, entered service in 1974. Initially the success of the consortium was poor, but by 1979 there were 81 aircraft in service. It was the launch of the A320 in 1981 that established Airbus as a major player in the aircraft market – the aircraft had over 400 orders before it first flew, compared to 15 for the A300 in 1972.

The A300 was the first airliner to use just-in-time manufacturing techniques. Complete aircraft sections were manufactured by consortium partners all over Europe. These were airlifted to the final assembly line at Toulouse-Blagnac by a fleet of Boeing 377-derived Aero Spacelines Super Guppy aircraft. Originally devised as a way to share the work among Airbuss partners without the expense of two assembly lines, it turned out to be a more efficient way of building airplanes (more flexible and reduced costs) as opposed to building the whole airplane at one site. This fact was not lost on Boeing, which, over thirty years later, decided to manufacture the Boeing 787 in this manner, using outsized 747s to ferry wings and other parts from Japan.

Variants

+A300B1+., +A300B2-100+.: 137 Metric Ton MTOW

+A300B2-200+.: 142 Metric Ton MTOW, with Kruger flaps

+A300B2-300+.: increased Maximum Landing Weight/Maximum Zero Fuel Weight

+A300B4+. The major production version. Features a center fuel tank for increased fuel capacity (47,500 kg). Production of the B2 and B4 totaled 248.

+A300B4-100+.: 157.5 Metric Ton MTOW

+A300B4-200+.: 165 Metric Ton MTOW

+A300B4-200FF+.: An A300 with a forward-facing crew compartment. The worlds first 2-crew widebody airliner. Includes some of the A310s and A300-600s digital avionics. First saw service with +Garuda+. in 1982, further customers were +VASP+., +Tunisair+. and +Kar-Air+./+Finnair+..

+A300B4-600+.: Referred to as the A300-600. See Below.

+A300C4+.: Convertible freighter version, with a large cargo door on the port side. First delivered to South African Airways in October 1982.

+A300F4-203+.: Freighter version of the A300B4-200. First delivery occurred in 1986, but only very few were built as the A300F4-200 was soon replaced by the more capable A300-600F (official designation: A300F4-600F).

+A300-600+.: Officially designated +A300B4-600+., this version is the same length as the B2 and B4 but has increased space because it uses the A310 rear fuselage and tail. It has higher power CF6-80 or Prattamp; Whitney PW4000 engines and entered service in 1983 with Saudi Arabian Airlines. A total of 313 A300-600s (all versions) have been sold.

+A300-600+.: (Official designation: A300B4-600) The baseline model of the -600 series.

+A300-620C+.: (Official designation: A300C4-620) A convertible freighter version. First delivery December 1985.

+A300-600F+.: (Official designation: +A300F4-600+.) The freighter version of the baseline -600.

+A300-600R+.: (Official designation: A300B4-600R) The increased range -600, achieved by an additional trim fuel tank in the tail. First delivery in 1988 to American Airlines; all A300s built since 1989 (freighters included) are -600Rs. Japan Airlines took delivery of the last new-built passenger A300, an A300-622R, in November 2002.

+A300-600RF+.: (Official designation: A300F4-600R) The freighter version of the -600R. All A300s delivered between November 2002 and 12 July 2007 (last ever A300 delivery) were A300-600RFs.

+A300-600ST+.: Commonly referred to as the Beluga or Airbus Super Transporter, these five airframes are used by Airbus to ferry parts between the companys disparate manufacturing facilities, thus enabling workshare distribution. They replaced the four Aero +Spacelines+. +Super Guppys+. previously used by Airbus.

+A300B10+. (A310) Introduced a shorter fuselage, a new, higher aspect ratio wing, smaller tail and two crew operation. It is available in standard -200 and the Extended range -300 with 9,600 km range in both passenger and full cargo versions. It is also available as a military tanker/transport serving the +Canadian Forces+. and +Luftwaffe+.. Sales total 260, although five of these (ordered by Iraqi Airways) were never built.

Courtesy Wikipedia

| Weight | 6 kg |

|---|---|

| Dimensions | 17 × 14 × 5.2 in |

Be the first to review “Airbus A300B Original House Livery Model” Cancel reply

Related products

Private & Civilian

Private & Civilian

Private & Civilian

Private & Civilian

Private & Civilian

Private & Civilian

Private & Civilian

Private & Civilian

Reviews

There are no reviews yet.